Sample preparation

The study used 125 bovine incisors, which were washed in distilled water and submerged in 0.1% thymol solution for 24 hours. Afterwards, the teeth were placed in distilled water, which was changed every 24 hours until the moment of use to avoid deterioration.

The vestibular surfaces of all teeth were cleaned by brushing with prophylactic cream (Detartrine, Septodont, France), washed, and dried with compressed air.

Seventy-five upper central incisor brackets (Victory Series®, 3M Unitek Dental Products, Monrovia, California, USA) were bonded to the vestibular surfaces of 75 teeth with Transbond Plus Self Etching Primer (3M Unitek Dental Products, Monrovia, California, USA) and Transbond XT Paste (3M Unitek Dental Products, Monrovia, California, USA) following the manufacturer’s instructions for each product. Excess resin around the bracket base was removed with a dental probe. Brackets were polymerized for 10 seconds on each side of the bracket with the SmartLite LED lamp (Dentsply®, USA) at 1250 W/cm2. The curing distance was 0 mm (surface contact).

Afterwards the teeth were covered with an acid-resistant nail varnish (60 Seconds nail varnish, Rimmel, London, UK) leaving 2 mm of enamel uncovered around each bracket. The 50 teeth that did not receive brackets were also covered in nail varnish leaving an area of exposed enamel of 2 × 4 mm.

Samples were stored in saliva for 24 hours at 37 °C, then bracket removal was performed using debonding pliers (678–219 0914, Hu-Friedy, Germany). Remaining adhesive material was removed from the enamel using a carbide tungsten bur (T21XR, Edenta Ag, Switzerland), followed by polishing with Soft-Lex discs (3M ESPE Soft-Lex tm. Dental Products, St Paul, USA). Adhesive removal was considered complete when the material was no longer visible under the light of the operatory lamp.

Experimental groups

The 125 teeth were divided into five groups (n = 25): Group 1) Intact enamel; Group 2) Intact enamel + demineralization cycles (DC); Group 3) Enamel after adhesive removal; Group 4) Enamel after adhesive removal + DC; Group 5) Enamel after adhesive removal + Profluorid + DC.

Varnish application

Profluorid® Varnish (VOCO GmbH. Cuxhaven, Germany) was applied to the enamel surfaces in Group 5, which had been cleaned and dried previously, following the manufacturers’ instructions. The varnish was left to dry for one minute before being placed in artificial saliva. Table 1 details the composition of Profluorid® Varnish.

Sample storage and demineralization cycles

Groups 1 and 3 were kept in artificial saliva at 37° for 8 days. The saliva composition used as storage medium was: 1% carmellose sodium, 13% sorbitol, 0.12% potassium chloride, 0.084% sodium chloride, 0.005% magnesium chloride hexahydrate, 0.015% calcium chloride anhydrous, 0.017% potassium phosphate dibasic, and 0.1% Nigapin® sodium. The saliva pH was adjusted and maintained at 6.5715.

Group 2, 4 and 5 samples were submerged in artificial saliva at 37 °C for 8 days, and subjected to demineralization cycles as follows: samples were placed in a demineralizing solution for 2 hours, three times per day, and returned to artificial saliva between the 2-hour cycles. Samples were washed in distilled water at each change of medium. The demineralization solution and the artificial saliva were changed every 48 hours14.

The composition of the demineralization solution was as follows: 2.2 mM calcium chloride (CaCl2 2H2O); 2.2 mM monosodium phosphate (NaH2PO4 7H2O); 0.05 mM lactic acid; pH was adjusted to 4.5 with 50% sodium hydroxide (NaOH)16.

Sample preparation for EDX/SEM analysis

Tooth surfaces in all groups were washed in distilled water and Group 5 samples were cleaned with a dental prophylaxis brush to eliminate the varnish before quantifying the enamel elements and examining the enamel morphology. All teeth were sectioned at the cement-enamel junction using a diamond disc (Komet Dental, Gebr. Brasseler GmbH & Co. Lemgo. Germany). Then, all crowns were given an ultrasonic bath for 60 minutes at room temperature in order to eliminate any remaining varnish from the surfaces, or any other impurity that might interfere with EDX and SEM observation.

EDX analysis

Twenty surfaces in each group were coated with carbon and analyzed using a JEOL-6100 scanning electron microscope (Jeol Ltd., Tokyo, Japan) equipped with an INCA energy dispersive X-ray microanalysis system (Oxford Instruments Analytical, Oxfordshire, U.K.) at 20 KV, with a counting time of 100 s per source.

The elements quantified were: Ca (weight %), P (weight %) and F (weight %). Using the Ca and P values obtained, Ca/P stoichiometric ratios were calculated using the following formula: Ca (mol)/P (mol) % = [Ca (weight %)/40.08 (g/mol)]/[P (weight %)/30.97 (g/mol)], the molecular masses of Ca and P being 40.08 and 30.97 respectively.

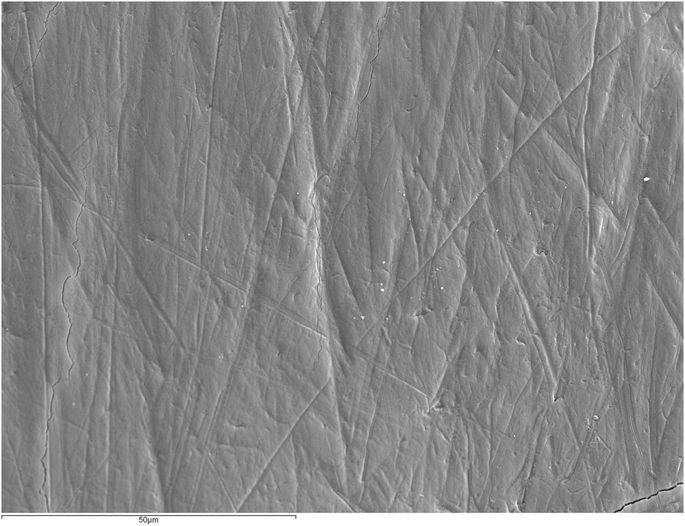

SEM analysis

Five samples from each group were coated with gold and examined under ×1000 magnification at 20 KV. The most representative images were captured and stored.

Statistical analysis

Statistical analysis was performed using the SPSS 19.0 statistical software package (IBM SPSS Inc., New York, USA).

Weight percentage values for Ca and P, as well as Ca/P stoichiometric ratios underwent the Kolmogorov-Smirnov normal distribution test (p < 0.05) and the Levene test for homogeneity of variance (p < 0.05). As they did not fulfill normality criteria (p > 0.05) or homogeneity of variance (p > 0.05), data were analyzed using the Kruskal-Wallis test (p < 0.05) and the Mann-Whitney test applying Bonferroni Correction (p < 0.005).