In today’s article, we’re going to take a temporary detour away from our normal holistic oral health subjects. Instead, we’re going to share one of the foundational principles that we use as a company as well as how we’ve applied this principle to our product solutions.

If you only like to read our work on topics like the mouth/body connection, the importance of the oral microbiome, and holistic oral health strategies that have stood the test of time, feel free to skip today’s article. But stay tuned to future articles because we’ll be returning to the world of holistic oral health. To hold you over until then, we invite you to check out our other articles, our free expert interviews, and our library of free ebooks.

In the meantime, let’s dive into today’s topic.

Many years ago, we learned about a strategy that was originally developed to help US fighter pilots improve their decision-making ability. Interestingly, we learned about this while attending a medicinal mushroom cultivation workshop with now world-renowned mycologist, Paul Stamets, but that’s another story…

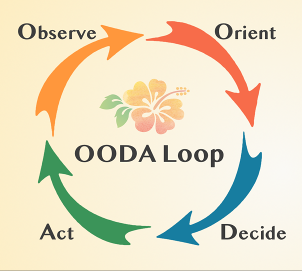

The strategy is called the OODA loop

OODA stands for Observe, Orient, Decide, Act.

While OODA was originally created to assist the armed forces, we’ve found it to be very helpful in both our personal and professional lives.

The wisdom and power of this strategy is in its repetition. When we cycle through multiple rounds of the loop, we can quickly navigate to improvement.

As a company, we apply this strategy for the development and improvement of all of our product solutions. For some examples of this, we can take a look at the OODA loops that we used to develop our BrushEco toothbrushes, to improve the packaging for our tongue cleaners, and to refine the production process for our Shine Remineralizing Tooth Whitening Powder.

OODA for BrushEco’s Development

We’ve participated in many beach cleanups throughout the years. As we gathered up the junk that was littering the beaches, we observed that the debris always included a bunch of used plastic toothbrushes.

We were determined to take steps to be part of the solution to this global plastic pollution issue, so we began to orient ourselves by looking into what it would take to create a more eco-friendly toothbrush option.

We were determined to take steps to be part of the solution to this global plastic pollution issue, so we began to orient ourselves by looking into what it would take to create a more eco-friendly toothbrush option.

During this “orient” step, we discovered that our original toothbrush production team didn’t have the equipment or setup to produce a more eco-friendly version of our Bass toothbrushes. So, we decided to find a production team that would be able to produce a Bass-style brush that’s made out of more sustainable materials.

Once we identified a team that was able to create brushes with our preferred style and materials, it was time to act. We created the first BrushEco prototypes. So, OODA really helped us get the ball rolling to turn this new product idea into a reality.

And, we continued to use the OODA loop to refine our BrushEco prototypes until we finally found the materials and specs that were just right. Then we were able to launch this product (woo hoo!). Here’s a link where you can learn more about BrushEco and its mission to help clean up existing plastic pollution, reduce new plastic pollution, and create healthier mouths, one toothbrush at a time.

OODA for Tongue Cleaner Packaging Improvements

Over time, we’ve been swapping out our packaging and product components for more sustainable options whenever they’ve become available (and we’ll continue to do so until we eventually reach 100% plastic-free).

When we discovered that there was a more sustainable way to package our stainless steel tongue cleaners, we leveraged the OODA loop yet again.

When we discovered that there was a more sustainable way to package our stainless steel tongue cleaners, we leveraged the OODA loop yet again.

To share a little background information, our stainless steel tongue cleaners used to have a plastic S clip that held the ends together so that the cleaner would fit nicely into its packaging. They were also wrapped in a plastic sleeve to be able to deliver to customers in a hygienic way.

We observed that a jute string could be used to hold the ends together instead of the plastic S clip and that we could produce a plastic free cardboard box to house the tongue cleaner.

Then we oriented ourselves by checking in with our tongue cleaner producers to see if they would be able to swap out the plastic clip for a jute string. We were super excited when they replied that yes, they could.

So, we decided to go ahead and act on this product packaging improvement idea. And now, our stainless steel tongue cleaners come with a jute string tied around the ends to help the cleaner fit into its paperboard product packaging. We successfully made this awesome tool’s packaging more eco-friendly and the only tongue cleaner on the market completely free of plastic packaging (and while we were at it, we changed the handles to make them a little easier to grip, too).

OODA for a Shine Production Improvement

We’ve always encouraged and empowered our amazing customer care team to listen very closely to customer feedback. (Yeah, just take a moment in the light, team. You all are amazing!)

We take note of the day-to-day feedback that you, our community, share with us via emails, phone calls, reviews, social media platforms, etc.

Using our normal “ear to the ground” strategy, our team observed a few people asking if we had changed the Shine formula because the most recent container of Shine that they purchased seemed like it had a slightly different texture than their Shine from previous orders.

Now that we’d observed this new information, to orient ourselves, we had a team meeting to discuss whether this was just a weird coincidence or if we needed to do some investigating. If you’ve been following us for a while, you probably know that we embrace continuous improvement (in all aspects of life). But to improve something, first you need feedback on your starting point. Three customers had contacted us to ask the same question about their Shine, which gave us a starting point to examine. We determined that this sounded like a possible opportunity for improvement rather than a simple coincidence.

We decided to investigate by grabbing a jar or bulk bag of Shine from that production run’s lot number and inspecting it ourselves.

We acted by simply pouring the Shine into our finest kitchen sieve.

And sure enough, we found that while most of the Shine passed right through the sieve, some of the xylitol did not. So that’s what was creating the difference in texture.

That completed one cycle through the OODA loop. Then it was time to start over from the new point of reference based on the information we gathered from the first OODA loop.

Round two of OODA for Shine improvement…

Observe: Ok, this production run of Shine has some xylitol in it that’s of a slightly bigger particle size than we’ve typically used.

Orient: Now that we’ve figured out what’s up, is it acceptable to just drop the topic without further investigation? Nope (that was a quick orient phase 😃). Often, once you orient, the questions come fast…

We were determined to answer questions like:

- Is this safe for customers to use? (Spoiler alert: we personally tested this batch of Shine in our own mouths and we discussed this with our production team’s chemist. Everyone found that yes, it was still safe to use.)

- How many units of Shine have been impacted? (Thankfully, not too many)

- How did this happen and how can we ensure it doesn’t happen again? (More on this below)

Decide: We decided to meet with our GMP-certified lab’s production team, including their professional chemist and quality manager. Their team loves to geek out on all things related to quality and process improvements, and sure enough, they showed up strong.

Act: In just a few hours, they:

- identified why there had been a slight change to the xyiltol’s particle size,

- isolated the affected production batch, and

- updated their processes to include particle size specifications to ensure that this doesn’t happen again.

Then in under one week, they began to work on an improved batch of Shine that was in alignment with our new process specifications (phew, we are blessed!).

The end result (for this round of improvements)

We like stories with happy endings :).

Thankfully, this texture variation issue was minor. In fact, it was so minor that the majority of folks who were using that batch of Shine (our own team members included) didn’t even realize that there had been a small change in texture.

After mindfully testing the batch of Shine with the slightly different xylitol particle size in our own mouths and after discussing this with our production team’s chemist, we found that that batch was still safe to use. The xylitol goes into solution so quickly with saliva that there was no risk of creating problems (which was a HUGE relief for us because our primary value as a company is to do no harm).

But the cool thing is that even though this situation wound up being very minor, it still helped us to identify an opportunity to refine our processes.

Shine is an all natural product that has always had some very minor texture variances from one batch to another due to its past default ‘acceptable range’ specifications. The variances were so minute that even though our entire admin team has been using Shine daily for years, we didn’t realize this.

We only discovered this when we started digging into the xylitol hiccup and our production gurus pointed this out and lined up different Shine samples they’d kept from each batch so we could feel each one and compare them all side by side (and even then, it was still difficult to detect the differences).

Thanks to the feedback that we received from those three customers about the xylitol particle size hiccup and the resulting OODA loops that we completed, we’ve now improved our processes by narrowing down the ‘acceptable range’ specifications so that Shine’s texture will be even more consistent going forward.

Wrapping up…

We hope that this has been a fun ‘behind-the-scenes’ look at our continual improvement strategies.

What about you? Have you ever used OODA before? Did you find it to be useful? Are there other strategies you’ve used to navigate the path of continual improvement in your professional or personal life? We invite you to share your ideas and experiences in the comments below so we can all learn from each other.

And if you’d ever like to give us feedback or if you have an idea for how we can improve our offerings, we’re all ears! Feel free to email us here so we can continue our exploration of continual improvement.