The present in vitro study was performed at the Department of Orthodontics and the Laboratory of Mechanical Engineering Faculty. Bioethical approval was obtained from the Lithuanian University of Health Sciences Bioethical Committee (No: BEC-OF-106) and the methods were carried out in accordance with the relevant guidelines. Informed consent was obtained from all subjects who participated in the study.

The power analysis with G*Power (Version 3.1.9.2)25 statistical software was used to determine the sample size. The parameters adopted were as follows: significance level of 5%, power test of 80%, the standard deviation of 3, and smallest effect of interest of 2. The calculation of the sample size was based on the following formula:

$$n = frac{{sigma^{2} left( {Zleft( {frac{alpha }{2}} right) + Zleft( beta right)} right)^{2} }}{{Delta^{2} }}$$

where n—the minimum sample size for each sample; Z(α/2) = 1.96 and Z(β) = 0.84 if α = 0.05 and β = 0.2; σ—standard deviation; Δ—the smallest clinically important difference.

$$n = frac{{3^{2} (1,96 + 0,8416)^{2} }}{{2^{2} }} = 17,66$$

The sample size calculation showed that at least 18 specimens were needed in each group.

Over a period of 1 month, 80 extracted unhealthy and incurable human molars were collected, remnants of blood and soft tissues were removed, and the teeth were washed under a stream of distillated water. Only the molars with intact enamel surface were used for the study: no decay, no restorations, no cracks from the tooth extraction forceps and no hypoplastic areas. Before the study, the teeth were kept in saline, changing it daily.

The teeth were randomly divided into 4 experimental groups (n = 20): two groups (hereinafter referred to as Fluoride Groups FG1 and FG30), which used chemically cured fluoride varnish (Bifluoride 10, VOCO GmbH, Cuxhaven, Germany), and another two groups (hereinafter referred to as Recaldent Groups RG1 and RG30), which used tooth mousse with bioactive calcium and phosphates (GC Tooth Mousse, GC Europe, Leuven, Belgium). In groups FG1 and RG1, brackets were bonded 1 day after the application of remineralizing agents, and in groups FG30 and RG30—30 days after application. The buccal surface of each tooth was divided into experimental (mesiobuccal) and control (distobuccal) (n = 80). As a result, 160 surfaces were used for the investigation. The brackets of the control group (distobuccal surfaces) were bonded and submitted to a tension test before applying the remineralizing agents to avoid contamination by them.

Before starting testing tensile bond strength, the buccal surface of each tooth was evaluated with a stereomicroscope (Stemi 2000-CS, Zeiss, Oberkochen, Germany) to assess the enamel cracks. The adhesive remnant index (ARI) was also evaluated after the brackets were debonded.

Remineralizing agents were applied according to the manufacturer’s instructions. The proximal buccal surfaces of each group (experimental group) were polished with a rubber cup and non-fluoridated pumice, rinsed with distillated water and dried with a stream of air. The experimental surface (mesiobuccal) of the Recaldent tooth mousse groups (RG1 and RG30) was coated with Recaldent tooth mousse (GC Tooth Mousse, GC Europe, Leuven, Belgium) using a micro brush and left for 5 min according to the manufacturer’s instructions, then rinsed with distilled water. The procedure was repeated every 6 h within the period of 5 days. Fluoride varnish (Bifluorid 10, VOCO GmbH, Cuxhaven, Germany) was applied on the mesiobuccal surfaces of the groups FG1 and FG30 according to the same protocol as in Recaldent tooth mousse groups26.

Then brackets from the first fluoride varnish group (FG1) and the first Recaldent group (RG1) were bonded and submitted to a tension test 1 day after application (T1). The teeth of the other two experimental groups (FG30 and RG30) were immersed in saline for 30 days (T2), changing it daily, and only then were brackets bonded and the teeth submitted to a tension test19.

Before the bonding procedure, the buccal surface of each tooth was polished with a rubber cup and non-fluoridated pumice, rinsed with water and air-dried. Following, the prepared enamel areas were etched with 37% phosphoric acid gel (i-GEL, i-dental Lietuva, Šiauliai, Lithuania) for 30 s, then washed and air-dried for 20 s until the surface appeared frosted. The etched buccal surface was coated with a thin layer of TruLock bond (Rocky Mountain Orthodontics, Denver, USA) and light-cured for 10 s (3 M ESPE Epilar, Neuss, Germany,1200 mW/cm2).

Directly afterwards, identical premolar metal braces (022 Roth, Discovery, Dentaurum, Ispringen, Germany) were bonded using light-cured TruLock adhesive resin (Rocky Mountain Orthodontics, Denver, USA). Each bracket was positioned 1 mm gingivally to the buccal cusp tip and pressed against the buccal tooth surface with an adapter using a force of 100 g (9.8 N), all done by the same person to ensure the standard thickness of the adhesive. A dental probe was used to remove residual adhesive around the bracket. Bracket adhesive was light-cured for 20 s (3 M ESPE Epilar, Neuss, Germany, 1200 mW/cm2)27, 28. All samples were kept in saline for 24 h after bonding to achieve complete resin polymerization.

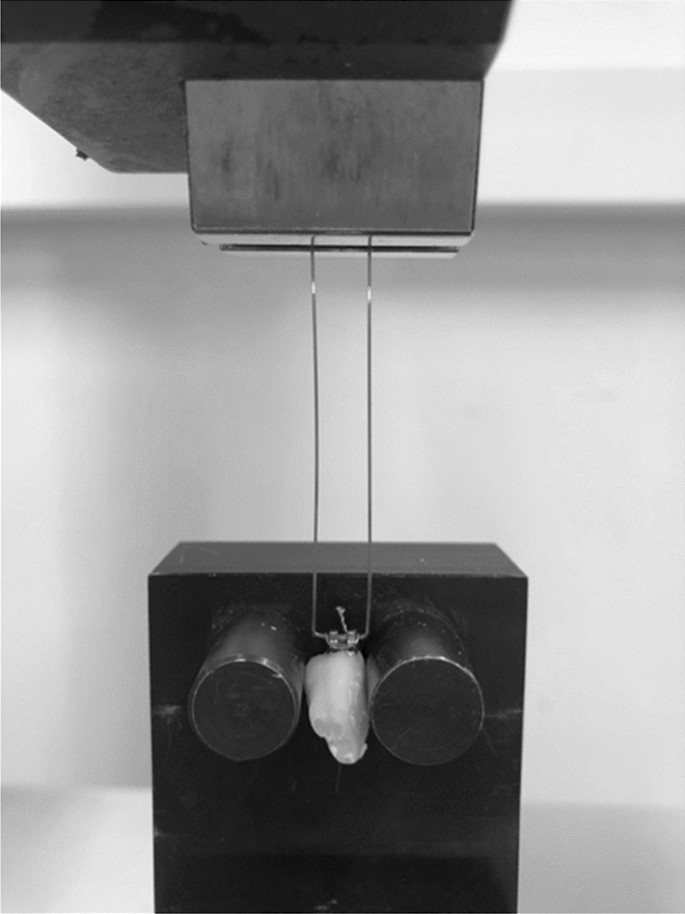

The tensile bond strength (TBS) was measured in the Department of Mechanical Engineering at the Kaunas University of Technology. The loops were bent from the orthodontic archwire and fixed to the brackets with ligatures (Fig. 1)20. Then they were adjusted to the universal mechanical testing machine (H24KT, Tinius Olsen, England). The testing machine was used at a crosshead speed of 5 mm/min until the bracket was debonded from the tooth. The highest debonding forces (N) of the brackets were recorded automatically by a digital software measurement system. The system consisted of a force sensor (SS50, Wagner Instruments, USA, 250 N × 0.1 N) and a controller with a display (BGI, Wagner Instruments, USA). TBS was calculated using the force’s value and the base of the bracket area value (1 MPa = 1 N/mm2)20.

Tooth fixed in universal testing machine.

After debonding the brackets, each bracket was analyzed with a stereomicroscope (Stemi 2000-CS, Zeiss, Oberkochen, Germany), and images were taken with a digital microscope camera (AxioCam, MRC 5, Zeiss, Oberkochen, Germany), which were superimposed on a 100 × 100 cell scale20. Adhesive residues were evaluated using the ARI index. The ARI values were divided into 6 groups according to the percentage of adhesive remnant on the bracket: 1—when there is no composite on the bracket base, 2—less than 20% of the composite remains on the bracket base, 3—composite residue covers 20–40% of the bracket base, 4—composite residue covers 41–60% of the bracket base; 5—composite residues cover 61–80% of the bracket base; 6—composite residues cover 81% or more of the bracket base20, 27.

Statistical analysis was performed using IBM SPSS 28.0.1.1. Tensile bond strength (TBS) data were analyzed by one-way ANOVA and Tukey posthoc methods of descriptive statistics. ARI data was analyzed by the Chi-Square method. The difference in results between the variables was considered statistically significant if p < 0.05.