In the present study, the thermo-mechanical properties of the photocurable resin TC-85, a newly developed material for direct 3D printed clear aligners, were evaluated by comparing them with those of PETG, which is a widely used thermoplastic material for fabricating conventional clear aligners.

The thickness of the PETG specimens thermoformed on the standardized maxillary incisors model was 0.41 mm, which was only 54.7% of the original thickness before thermoforming (0.75 mm). This behaviour has been previously corroborated. Min et al. reported a 57.5% decrease in thickness of the materials that were thermoformed on a standardized maxillary incisors model representing the volume of teeth applied in clinical practice13. Further, a study of thermoforming thermoplastic materials using a square block with a thickness of 10 mm reported a thickness decrease by approximately 74.9–92.6%12. Therefore, it is apparent that conventional thermoplastic materials show various thickness changes after thermoforming, depending on the size and shape of the models.

In clinical practice, since clear aligners are manufactured using dental models of patients with different anatomical structures such as teeth size, dental arch size, alveolar bone height, and palatal vault depth, irregular thickness changes may occur. It has also been demonstrated that within a clear aligner, the thickness varied for each region such as the incisors, molars, and edentulous areas22. Since the thickness of the aligners is the factor that has the greatest influence on the orthodontic force applied to the teeth13,23, the irregular thickness of the clear aligners makes it difficult for clinicians to predict the performance of the clear aligners and the outcomes of the treatment. If the clear aligners are manufactured by 3D printing, it is possible to decrease the variation in thickness and increase the predictability of treatment outcomes. Moreover, if the technology is further developed, the thickness can be modified according to the type of tooth movement and regions, in turn potentially increasing the efficiency of the treatment in clinical practice.

Currently, 3D printed clear aligners using TC-85 material are generally manufactured by a digital lighting processing (DLP)-type 3D printer with layer thickness set to 100 μm. Residual resin remaining on the surface of the printed aligners is removed using a soft scraper and alcohol. Finally, they are post-cured under N2 with UV light using a post-curing chamber. The specimens of TC-85 in this study were manufactured by the same procedure (detailed procedures are described in the “Materials and methods”).

The thickness of the printed TC-85 specimens was 0.56 mm, which was 12% thicker than the set value (0.5 mm). Because the DLP-type 3D printer cures the liquid photosensitive resin using a high-definition projector as a light source, the resin can be polymerized thicker than the set value. A previous study described that the over-penetrance of light in 3D printing with transparent materials can induce overbuilding24. In addition, although the liquid resin on the surface of the specimens was mechanically removed after 3D printing, residual resin that remained was polymerized during the post-curing process18, which could result in a thicker specimen.

Overbuilding during 3D printing prevents the clear aligners from being fully seated on the teeth. In addition, excessive orthodontic force may be applied to the teeth by the clear aligners18. Overbuilding can be reduced and accuracy can be increased by setting the layer thickness of the 3D printer to 50 μm or printing with a stereo lithography apparatus (SLA)-type 3D printer25. However, because SLA-type 3D printers print each part with a laser source, it takes a longer time to fabricate the whole object. It is difficult to apply the SLA-type printer in clinical practice where multiple stages of clear aligners must be manufactured.

When 3D printing the clear aligners, the offset should be considered to improve the fit of the aligners. For example, in a study where splints were manufactured by the DLP-type 3D printer, a higher fit was observed when the offset was 0.1 mm26. Therefore, to apply the newly developed TC-85 to clinical practice, further studies are required to establish the offset setting, calibration, and workflow conditions.

The yield strength and elastic modulus were significantly higher in PETG than in TC-85 (Fig. 1), while the elastic range was significantly larger in TC-85 (4.65%) than in PETG (3.92%). With conventional clear aligners manufactured by thermoplastic materials, it is recommended to perform tooth movement of 0.25–0.33 mm per step and activate it once every two weeks for effective orthodontic tooth movement21,27. These results indicate that owing to the higher flexibility and larger elastic range of the clear aligners manufactured using TC-85, more tooth movement can be performed per step without permanent deformation.

Regarding the stress relaxation and creep behaviour, at 37 °C, when a load was applied for 60 min, TC-85 initially showed a rapid stress relaxation; after 13 cyclic loads, a residual static force of 1.0 N was observed. Although the stress relaxation occurred in PETG, the amount of relaxation was smaller than that of TC-85, with a residual static force of 11.39 N after 13 cyclic loads. The stress relaxation and creep behaviour of TC-85 offers these clear aligners with greater flexibility and improved fitting after being worn in the oral cavity28.

In addition, by constantly applying a light force to the teeth, it is possible to induce a physiological movement of the teeth29 and reduce the discomfort of the patient. In clinical practice, an orthodontic force of 0.098–1.18 N is recommended depending on the types of tooth movement30. Excessive force may have side effects on the teeth and surrounding tissues, including root resorption, and an orthodontic force applied beyond the pain threshold of the patients will result in discomfort13. The static force shown by TC-85 at 37 °C was appropriate to apply an orthodontic force. However, the large initial static force of TC-85 may induce discomfort to the patients when inserting the aligner. Also, since a large amount of stress relaxation occurs, the predictability of the aligner may deteriorate.

In TC-85, as the load cycle was repeated, the rate of strain recovery increased and the residual static force after relaxation also showed a gradual increasing pattern. The crystallization in the amorphous portion of the material by tensile stress may induce this behaviour31,32,33. In PETG, the residual static force and strain recovery rate remained relatively constant even after repeated cyclic loads. In clear aligners, the force decay is generated because of the viscoelastic properties of the material and the permanent deformation caused by repeated insertion of the aligners. It has been previously shown that a three-point bending test on materials of the clear aligners resulted in a 10–17% decrease in the static force after repeated loads13. The creep behaviour of TC-85, with the gradually increasing static force under cyclic loads, may be more advantageous in respect to clinical performance, as force decay is reduced, maintaining the orthodontic force of the aligners.

The creep and stress relaxation behaviours of TC-85 and PETG at 80 °C differed from those at 37 °C. TC-85 showed a slight stress relaxation, and after 13 cyclic loads, the static force was 0.12 N, whereas PETG exhibited a rapid stress relaxation and showed low static force as 0.01 N. At 80 °C, the interaction between the polymer chains of both materials is weakened; therefore, their storage modulus and elasticity decrease. However, owing to the cross-linked structure of TC-85, it is highly stable; therefore, it was able to maintain a constant stiffness while also retaining the static force and strain recovery patterns after repeated loads. PETG, a non-cross-linked polymer, showed a pattern of gradual increase in the static force under the cyclic loads and the strain recovered to a negative value. At 80 °C, the interactions between the polymer chains of PETG are weakened, allowing the movement of chains; therefore, thermal shrinkage was generated32,34.

TC-85 has geometric stability at high temperatures without heat shrinkage as demonstrated, which can be an advantage in clinical practice. Manufacturing clear aligners with TC-85 renders the hygiene management and disinfection of the aligner feasible. Generally, microorganisms begin to colonize the clear aligner surface 6 h after inserting the aligner35, and the deposited biofilm prevents the full coverage of the dentition with the clear aligners, thereby resulting in unaccomplished tooth movement36. However, clinicians advise patients not to clean or disinfect the aligners at high temperatures because the thermoplastic materials such as PETG deform. A thermophysiology study has indicated that Streptococcus mutans and related lactic acid bacteria, which are the major causative organisms for dental caries, are inactivated at temperatures above 60 °C37. Further studies are required to verify that washing the aligners at high temperatures does not affect their performance and has a disinfection effect in actual clinical practice.

As determine by DMA, the Tg of TC-85 (69.85 °C), estimated through the peak of the loss tangent (tan δ), was approximately 30 °C lower than that of PETG (101.8 °C). Although PETG is a non-cross-linked polymer, it contains aromatic rings; thus, the polymer chains form a strong pi-pi stacking interaction38. The polymer chains of TC-85 form a cross-linked structure through a difunctional oligomer, owing to the low molecular weight of the monomer, and the interaction between the polymer chains is weaker than that of PETG. Therefore, at 37 °C, TC-85 showed a lower storage modulus, a larger loss tangent (tan δ), and lower elasticity than PETG. Therefore, TC-85 displayed viscous behaviour, i.e., the strain gradually recovered upon removing the load and a large amount of stress relaxation was observed. At 80 °C, the interaction between the polymer chains decreases; therefore, the storage moduli of TC-85 and PETG reduced to 3.62 MPa and 1043.50 MPa, respectively. Although the storage modulus of PETG was significantly higher than that of TC-85, unlike the latter, PETG does not have a cross-linked structure that can restrain chain movement, resulting in a significant increase in the amount of stress relaxation. Furthermore, as movement between chains became possible, thermal shrinkage occurred. In contrast, TC-85 maintained a constant static force and strain recovery because the cross-linked structure stabilized the movement between the chains.

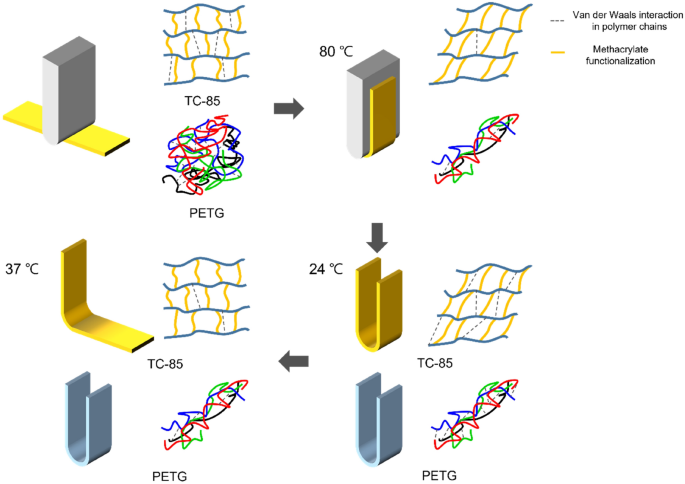

At a higher temperature of 80 °C, the Van der Waals interaction was significantly weakened and the polymer chain movement became possible. At a lower temperature of 24 °C, the Van der Waals interaction was re-formed and the shape of the specimens was fixed. Although 37 °C is lower than the Tg of TC-85, sufficient energy was supplied to enable the polymer chain movement; in addition, frozen stress was released. TC-85, which was cross-linked like a mesh, realized shape recovery39. Approximately 90% of the deformation rapidly recovered to its original shape within 10 min, and after 60 min the shape recovery ratio was 96%, exhibiting excellent shape memory properties. However, PETG, which is not cross-linked, like a thread, did not recover its original shape (Fig. 5).

Shape memory property test procedure and shape memory mechanism; Yellow and blue specimens indicate TC-85 and PETG, respectively.

Owing to the shape memory property of TC-85, the aligners can constantly apply orthodontic forces to the teeth under normal body temperature conditions without force decay caused by the deformation of the aligners. It also presents an advantage when the patients wear the aligners. Before applying the aligners, patients can immerse them in warm water to render them flexible, which can reduce the discomfort upon wearing them and provide a better fit. Even if the aligner is deformed along the dentition, its original printed shape and stiffness will be recovered at 37 °C. Therefore, the aligners can apply a constant orthodontic force to the teeth. In this study, the shape memory property was qualitatively evaluated and the property was visualized through a bending test. However, further studies such as the tension test are required in the future.

This study evaluated the basic mechanical properties of the photocurable resin TC-85, a newly developed material for 3D printed aligners, and only one type of the thermoplastic materials, PETG, was compared as a control. Therefore, it is difficult to conclude that TC-85 is superior to all the conventional materials used for manufacturing the clear aligners. However, since all conventional thermoplastic materials are non-cross-linked polymers, the variation in mechanical properties according to temperature will show a relatively similar pattern. They are not geometrically stable at high temperatures and have no shape memory property. Therefore, TC-85 presents favourable properties and demonstrates significant advantages for the clinical application of aligners.